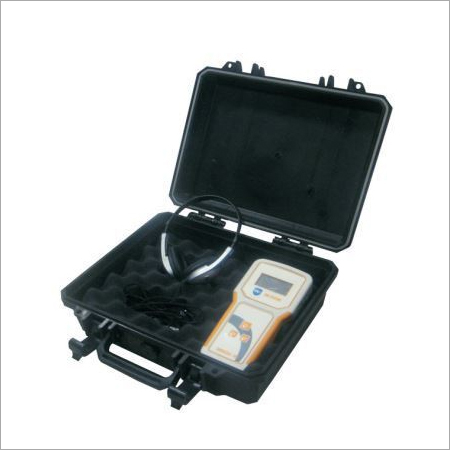

Ultrasonic Leak Detector

Product Details:

Ultrasonic Leak Detector Price And Quantity

- 30000.00 - 120000.00 INR/Piece

- 1 Piece

Ultrasonic Leak Detector Trade Information

- Telegraphic Transfer (T/T)

- 4 Piece Per Week

- 2 Week

- Eastern Europe Middle East Western Europe Africa Asia

- All India

- CE

Product Description

This Ultrasonic Leak Detector from USL Series ultrasonic detectors is a reliable and economical instrument that can detect seal failures and minute leaks within vacuum system, compressed air system, industrial equipment and machine. This instrument is a part of predictive and systematic repair which can avoid downtime by locating the area of defect. This UL-102 can locate the defects and estimate their magnitude. It can regularly check ball bearings, valves, gates, fittings and steam trap, in addition to continual inspection of gear, pump and engine. Leak tightness of steam traps, valves and slide valves can be inspected by monitoring and studying the flow noise.

This energy saving instrument can detect leaks & mechanical malfunctioning, assess steam trap, diagnose critical valve, etc.

An ultrasonic transmitter can be added to control of the leak tightness of cabins, windows, doors and devices.

For Detecting Leaks & Mechanical Malfunctioning

- Predictive Maintenance

- Range : 30 KHz , 40KHz

- Energy Savings

- Leak Detection

- Steam Trap Assessment

- Critical Valve Diagnostics

- Electrical Arcing & Corona Discharge occurs.

- The USL Series ultrasonic detectors are designed for the Rapid, Reliable and Cost-Effective detection of seal

failures and minute leaks within compressed air systems and networks, vacuum systems, industrial equipment

and machinery. Predictive & systematic repairs can avoid expensive disturbances and unscheduled downtime.

Identifying the exact location of a defect entails a quick reaction time to prevent major damages.

With UL-102 it is possible to locate precisely the defects and estimate their magnitude. Its fast and easy

operation can save time, material, energy and condensate losses with a regular checking of fittings, valves and

gates, steam trap, ball bearings. The regular inspection of engines, pumps and gears using UL-102 leads to

increased operational reliability and guarantees a higher degree of availability of machinery. With the

monitoring and study of the flow noise the inspection of the leak tightness of valves, slide valves and steam

traps is also possible.

The UL-102 can be used to detect leaks in pressure-less systems, such as vehicles, freight containers, other types of containers and ventilation technique systems, where no ultrasound is generated. The UL-102 generates ultrasonic waves which emerge at the leak points. Precise location is carried out from the outside with the UL-102. The option of an additional ultrasonic transmitter allows the control of the leak tightness of windows, doors, cabins and devices with little additional expense.

Specification

| Probe | Airborne for external sound Touch probe for internal sound |

| Sensitivity | -65 Db/ubar at 40 KHz |

| Frequency Ranges | UL 101 : 40KHz 1 |

| Band Width | 2 KHz |

| Displays | Alphanumeric Graphics LCD |

| Headset | Dynamic 32 ohm |

| Power Supply | 6 V Internal NiMH rechargeable battery |

| Weight | 175 grams |

| Dimension | 166 x 88 x 32 |

| Case | High impact ABS Plastic |

| Operating Temp. | 0-50 C |

| Storage Temp. | -20 C to 60 C |